In today’s competitive manufacturing landscape, precision is crucial. Top-tier molds are essential for efficiency, and China leads in this sector with its expertise and innovation. High-quality molds ensure precise production, reflecting China’s commitment to excellence and technological advancement. China’s mastery of mold manufacturing, with its innovative design and advanced materials, revolutionizes die casting, enhancing efficiency and reliability globally. Combining traditional craftsmanship with modern technology, China mold industry plays a vital role in optimizing die casting operations worldwide.

Understanding China Mold Manufacturing

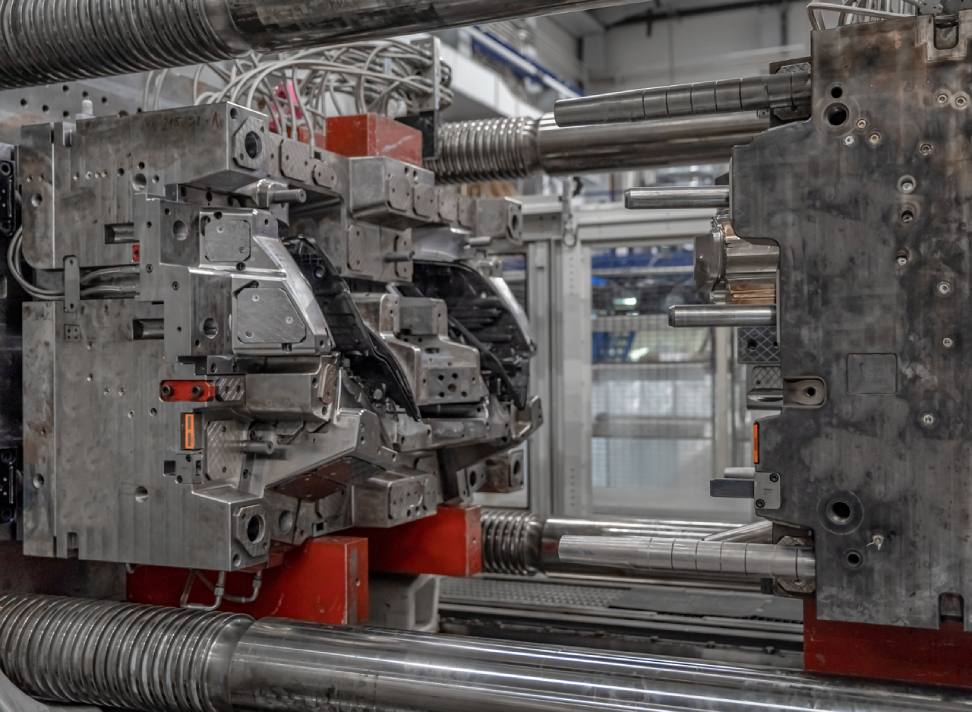

China’s mold manufacturing prowess is underpinned by a robust infrastructure characterized by cutting-edge machinery, a highly trained workforce, and rigorous quality control standards. The country’s extensive investment in advanced technologies has propelled its manufacturing sector to the forefront of the global stage. Companies across China leverage state-of-the-art equipment, including CNC machining, EDM (Electrical Discharge Machining), and CAD/CAM software, to craft molds with unparalleled precision and consistency.

The integration of these technologies enables manufacturers to achieve intricate designs, tight tolerances, and complex geometries with remarkable accuracy. CNC machining, for instance, facilitates automated production processes, ensuring repeatability and efficiency in mold fabrication. Similarly, EDM utilizes controlled electrical discharges to precisely shape molds, allowing for intricate details and fine finishes. CAD/CAM software serves as the backbone of design and manufacturing, enabling seamless communication between designers and production teams, thereby streamlining the entire manufacturing workflow.

Moreover, China’s skilled labor force plays a pivotal role in upholding the quality standards of mold manufacturing. With specialized training and expertise, workers adeptly operate advanced machinery, ensuring the production of molds that meet stringent quality requirements. This synergy between technological innovation and skilled craftsmanship positions China as a global leader in mold manufacturing, offering unparalleled capabilities and solutions to industries worldwide.

Advantages of Choosing China Mold

1. Cost-Effectiveness

Benefiting from competitive labor costs and streamlined production processes, China presents cost-effective solutions for mold manufacturing while maintaining exceptional quality standards. This combination of factors enables businesses to achieve significant cost savings without sacrificing the precision and reliability of their molds.

2. Diverse Expertise

China’s wealth of experience across diverse industries provides manufacturers with access to a broad spectrum of mold designs and materials customized to their precise specifications and needs.

3. Quality Assurance

China’s commitment to maintaining rigorous quality control protocols underscores its dedication to producing molds that surpass international standards, guaranteeing unparalleled performance and durability. These protocols encompass a comprehensive array of measures implemented throughout the manufacturing process, from meticulous material selection to stringent final inspections. By leveraging cutting-edge technologies and advanced testing methodologies, such as coordinate measuring machines and non-destructive testing techniques, China ensures that every aspect of mold production is scrutinized with precision. This unwavering attention to detail and commitment to excellence solidifies China’s position as a global leader in mold manufacturing, trusted by industries worldwide for superior quality and reliability.

Die Casting in China: Unleashing Efficiency

Die casting stands as a widely embraced manufacturing process, entailing the injection of molten metal into a mold cavity under intense pressure. China’s proficiency in mold manufacturing augments the die casting procedure in numerous aspects, propelling efficiency and precision to new heights.

1. Precision Engineering

China molds are meticulously engineered with unparalleled precision, enabling the realization of intricate designs and the maintenance of tight tolerances critical for die casting applications. Through advanced design methodologies and state-of-the-art manufacturing techniques, China ensures that every aspect of the mold meets exacting specifications. This precision engineering not only facilitates the production of complex components with intricate geometries but also enhances the overall efficiency and reliability of the die casting process. By consistently delivering molds of exceptional quality and precision, China solidifies its reputation as a global leader in the field of mold manufacturing.

2. Enhanced Durability

China molds leverage advanced materials and innovative surface treatments to achieve enhanced durability and extended longevity, thereby mitigating downtime and reducing maintenance costs. Through the integration of cutting-edge materials such as high-performance alloys and specialized coatings, China ensures that its molds withstand the rigors of repeated use and harsh operating conditions with remarkable resilience. These advancements not only extend the operational lifespan of molds but also contribute to increased productivity and cost savings by minimizing the need for frequent repairs and replacements. By prioritizing durability and longevity, China reaffirms its commitment to delivering molds of unparalleled quality and reliability to industries worldwide.

3. Streamlined Production

The efficient mold production processes implemented in China play a pivotal role in facilitating streamlined die casting operations. By leveraging advanced technologies, skilled labor, and optimized workflows, China’s manufacturers ensure that molds are fabricated swiftly and accurately. This streamlined production not only enhances efficiency but also minimizes delays, allowing for the precise scheduling and timely delivery of components to clients. Moreover, by maintaining rigorous quality control measures throughout the production process, China guarantees that each mold meets the highest standards of performance and reliability, further reinforcing its reputation as a trusted provider of die casting solutions on the global stage.

Conclusion

In conclusion, leveraging the capabilities of China’s mold manufacturing industry holds the promise of revolutionizing your die casting china processes. This means tapping into cost-effective solutions, ensuring superior quality, and achieving unmatched efficiency. Collaborating with reputable manufacturers in China empowers companies to not only retain but also enhance their competitive edge within the current market landscape. Moreover, such partnerships facilitate the cultivation of innovation within their manufacturing endeavors, driving progress and prosperity in the industry.

Also read