The plastic molding industry is under increasing pressure to adopt sustainable practices.The plastic molding industry is under increasing pressure to adopt environmentally responsible practices. This shift towards sustainability is driven by growing consumer awareness, regulatory mandates, and the depletion of natural resources.

The industry is responding by implementing various strategies to reduce its environmental impact while maintaining production efficiency and product quality. This article explores key areas where sustainability can be integrated into the plastic mold process.

This shift towards environmental responsibility is driven by growing consumer awareness, regulatory mandates, and the depletion of natural resources.

Material Selection and Utilization

Recycled Plastics: Incorporating recycled materials into the production process reduces the demand for virgin plastics, minimizing environmental impact.

Bio-Based Plastics: Utilizing plastics for die casting mold that is derived from renewable resources such as corn starch or sugarcane can lower carbon emissions.

Material Optimization: Selecting materials with the lowest environmental impact while meeting product performance requirements.

Design for Recyclability: Designing products and molds to facilitate recycling and reduce waste.

Energy Efficiency and Waste Reduction

Energy Audits: Conduct regular energy audits to identify areas for improvement and implement energy-saving measures.

Equipment Upgrades: Investing in energy-efficient machinery and equipment.

Waste Minimization: Implementing lean manufacturing principles to reduce material waste, scrap, and energy consumption.

Water Conservation: Implementing water-saving technologies in cooling systems and other processes.

Circular Economy Principles

Closed-Loop Systems: Establishing systems to recover and reuse plastic waste within the production process.

Product Lifecycle Management: Designing products with end-of-life considerations, facilitating recycling or reuse.

Collaboration: Partnering with recycling and waste management companies to optimize material recovery.

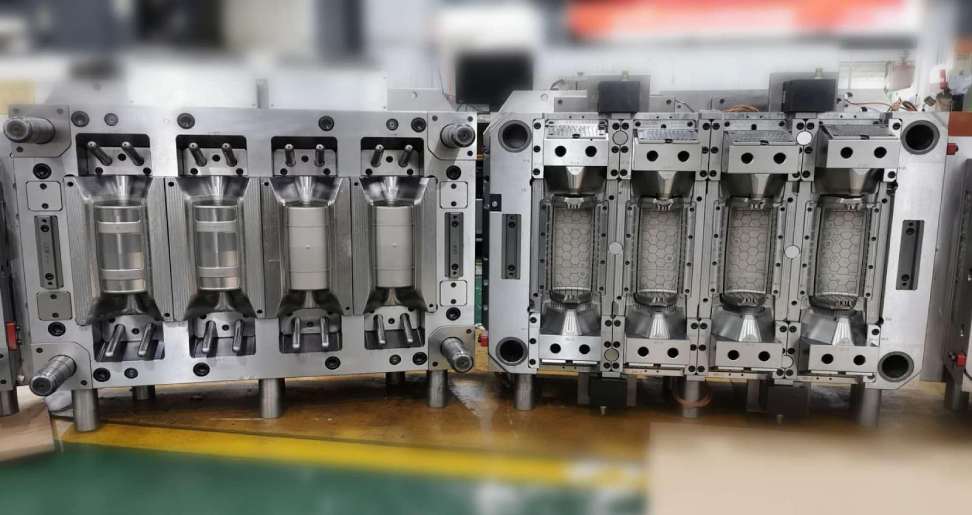

Mold Design and Manufacturing

Sustainable Materials: Using recycled or sustainable materials for mold construction.

Mold Life Optimization: Extending mold life through proper maintenance and repair to reduce waste.

Energy-Efficient Molding Processes: Implementing technologies to optimize cooling and heating cycles.

Supply Chain Sustainability

Supplier Assessment: Evaluating suppliers based on their environmental practices and sustainability initiatives.

Collaboration: Working with suppliers to develop sustainable packaging and transportation solutions.

Measuring and Reporting

Environmental Performance Indicators (EPIs): Establishing key performance indicators to track environmental impact.

Transparency: Reporting on sustainability efforts to stakeholders.

Certifications: Pursuing environmental certifications to demonstrate commitment to sustainability.

By adopting these sustainable practices, the plastic molding industry can contribute to a greener future while maintaining competitiveness and profitability.

Would you like to explore specific case studies or delve deeper into a particular aspect of sustainable plastic molding?

Conclusion

The plastic molding industry is undergoing a critical transformation towards sustainability. By adopting practices focused on material selection, energy efficiency, waste reduction, and circular economy principles, manufacturers can significantly reduce their environmental impact.

Implementing these sustainable practices not only benefits the planet but also enhances brand reputation and can lead to cost savings. As consumer awareness and regulatory pressures increase, embracing sustainability becomes imperative for the long-term success of the plastic molding industry.

By working collaboratively with suppliers, customers, and industry stakeholders, the plastic molding sector can drive positive change and contribute to a more sustainable future.

Would you like to explore specific case studies or delve deeper into a particular sustainable practice?

Also read

Feature Image Source: https://tinyurl.com/jjuddc8x